About Us

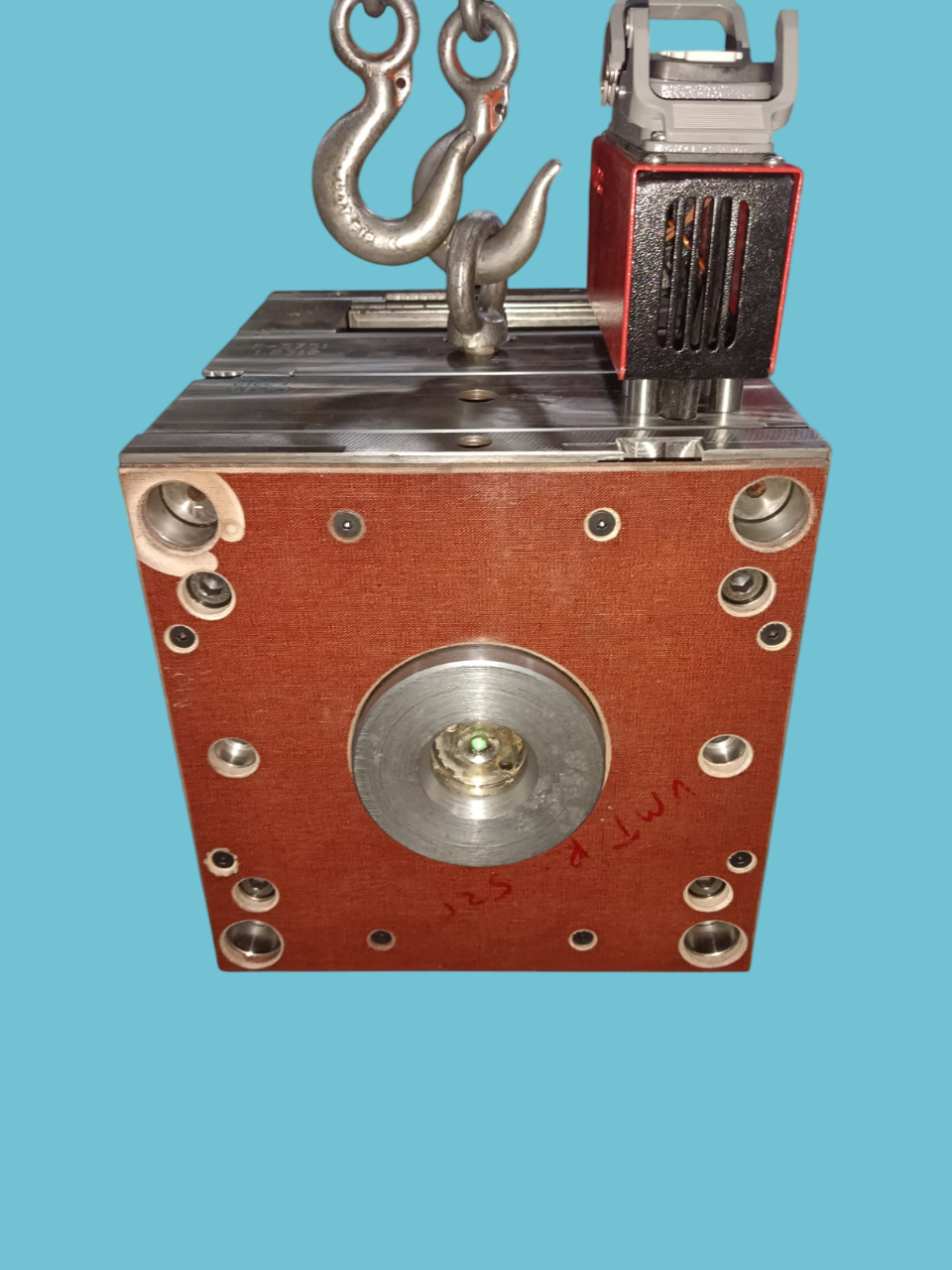

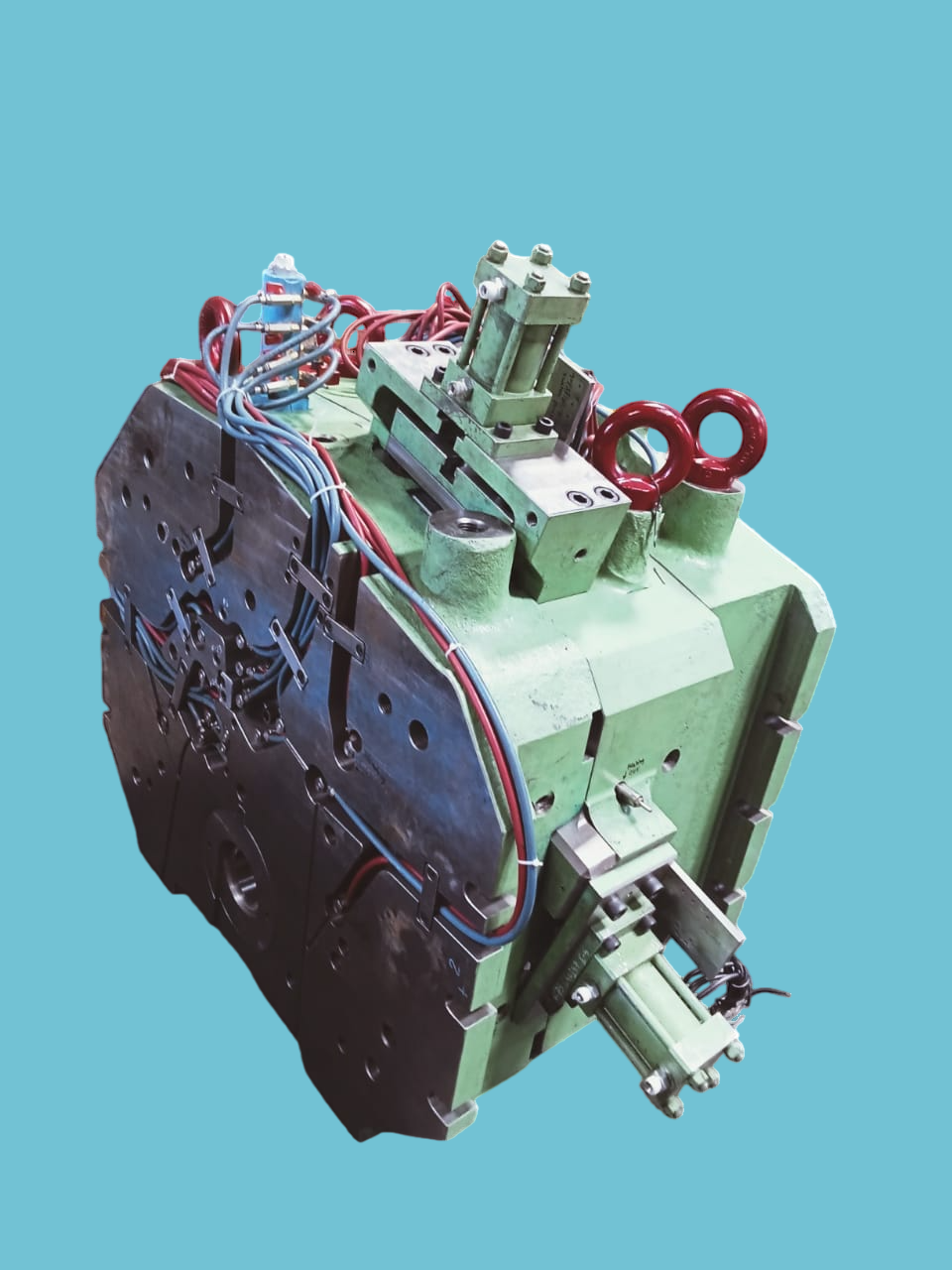

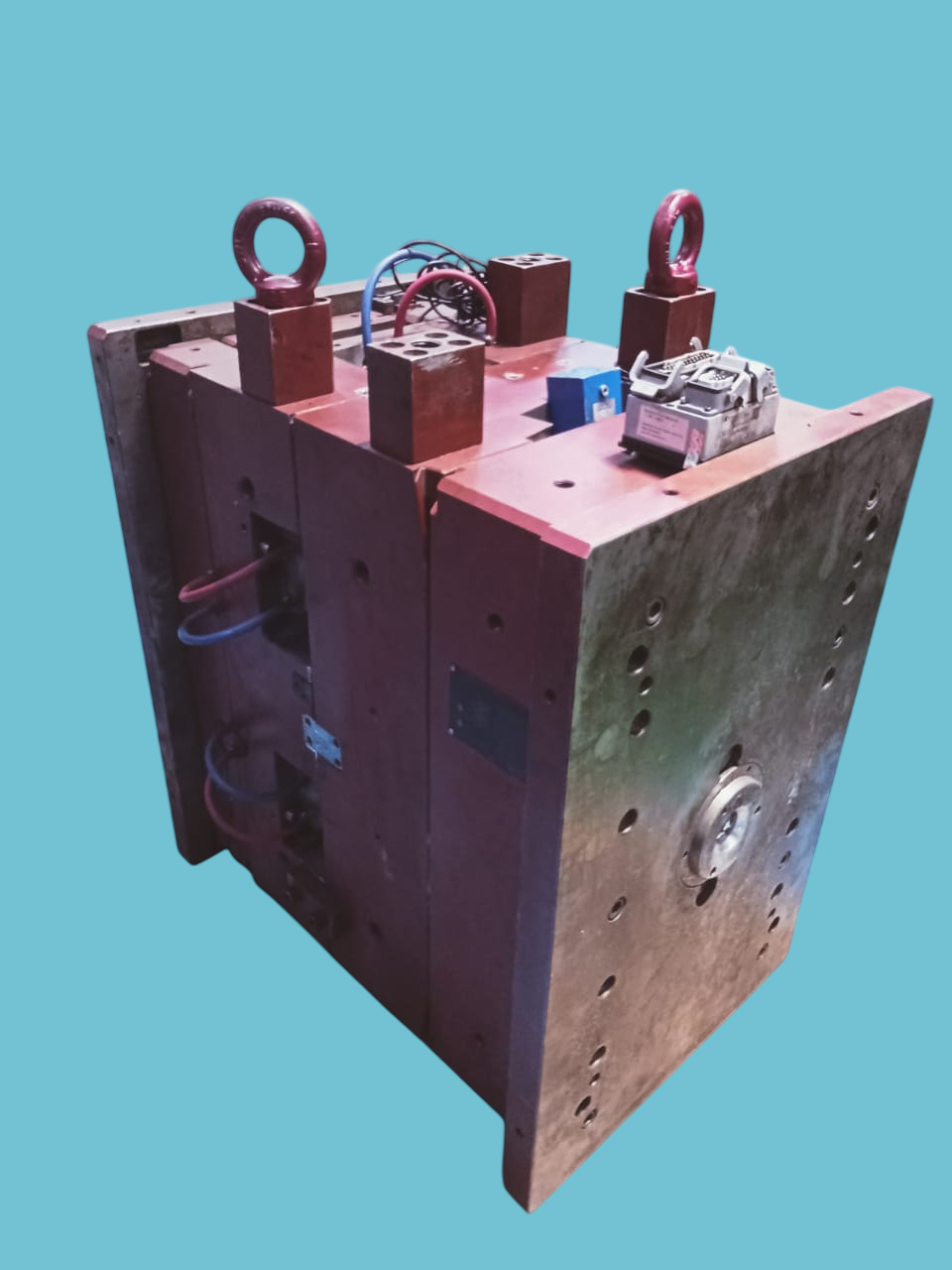

"Die & Mould Solutions: A Leading Manufacturer Specializing in

Plastic Injection Moulds and Pressure Die Casting Dies"

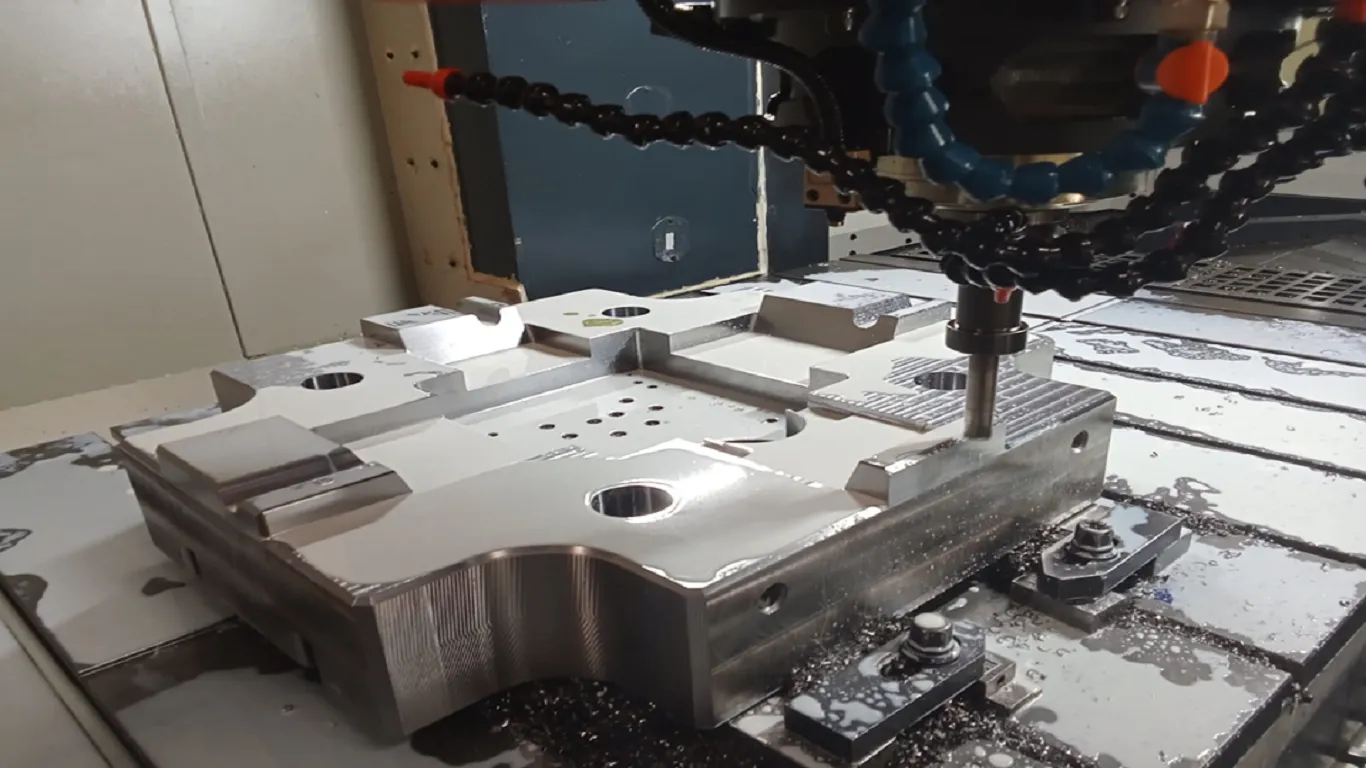

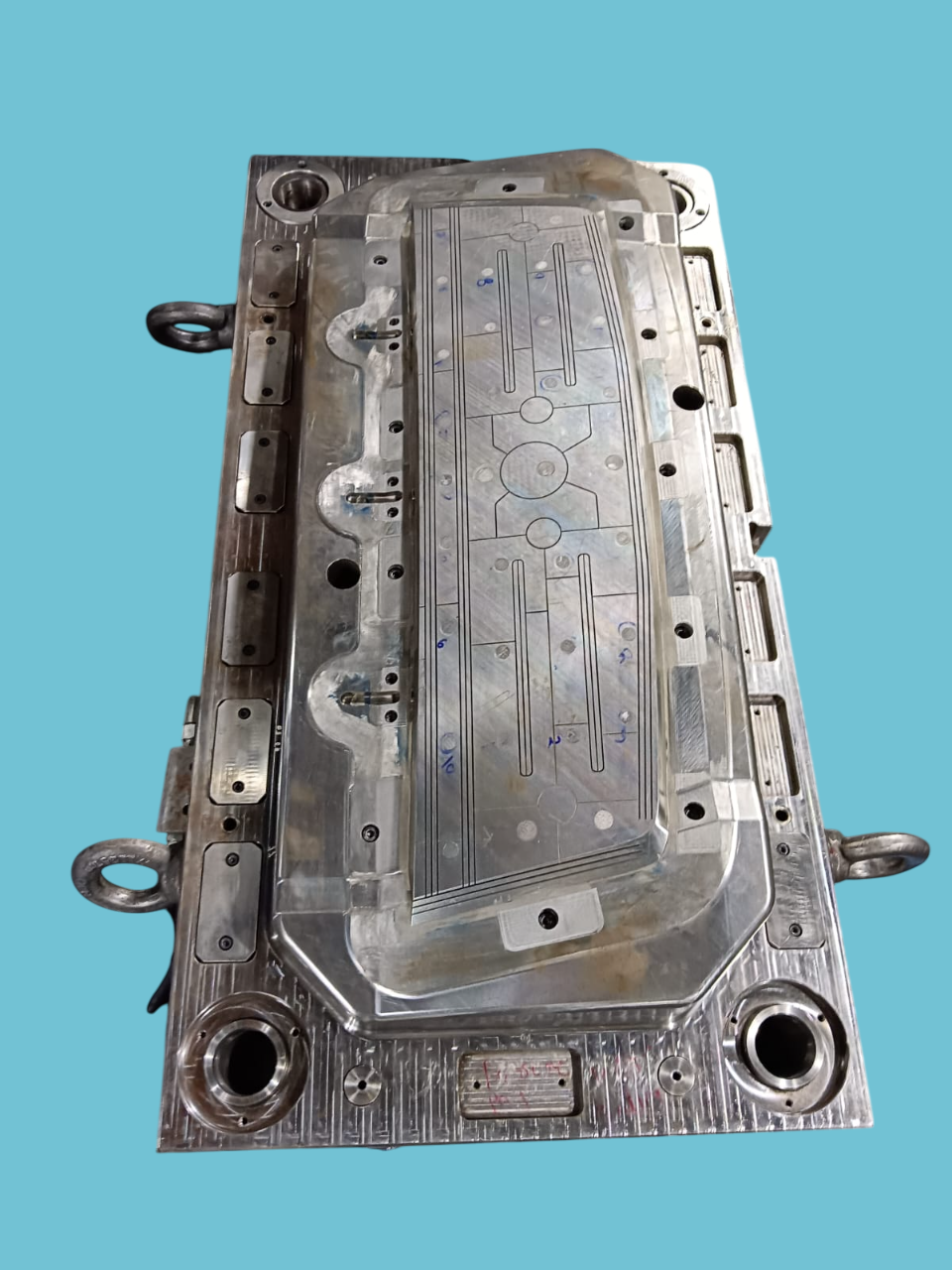

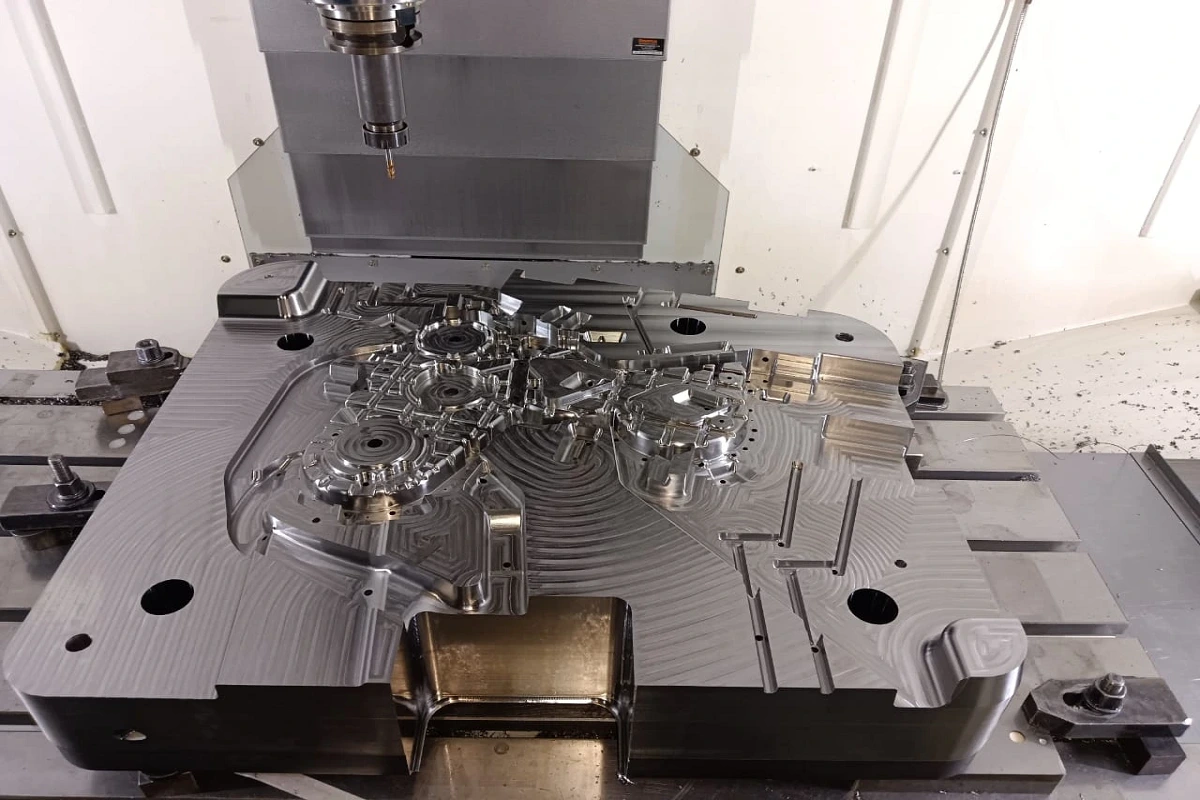

Die & Mould Solutions are expert in tool design & manufacturing of

plastic mould & pressure die casting dies.

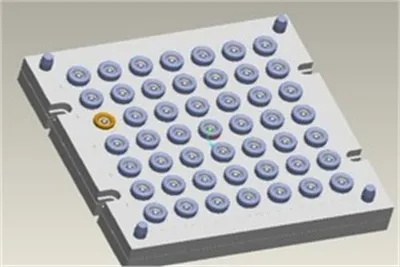

Our Company manufacturer of plastic injection moulds, investment

casting dies, VMC job work, EDM job work, drilling job work &

Design

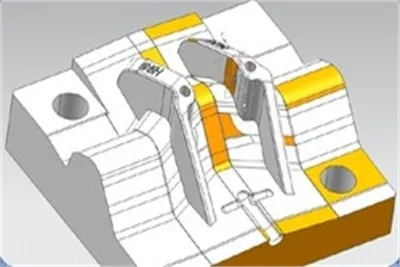

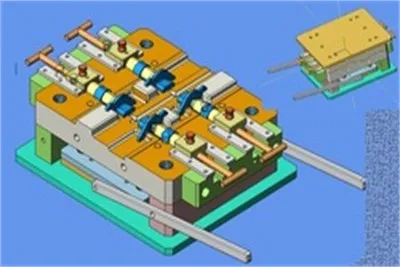

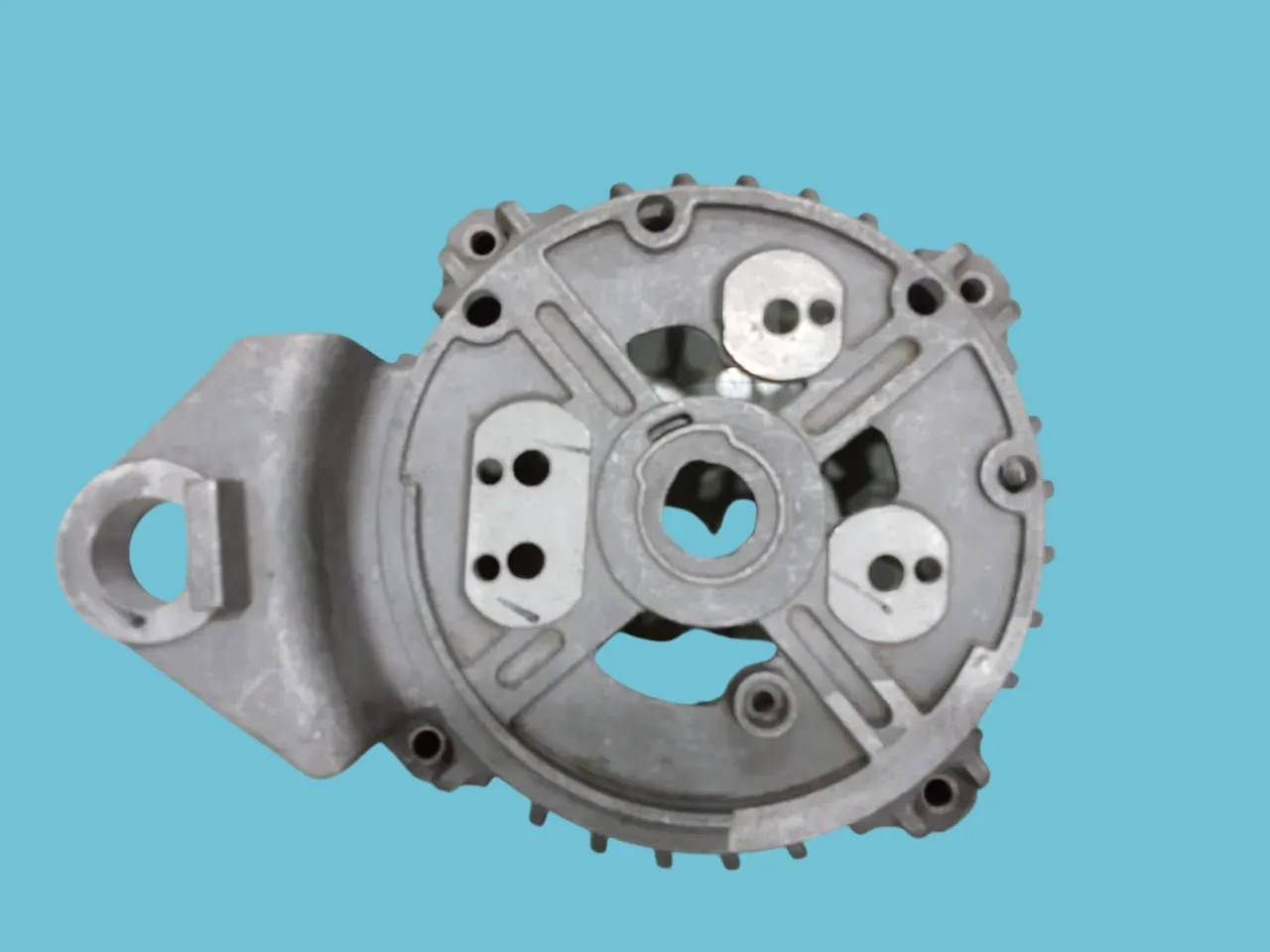

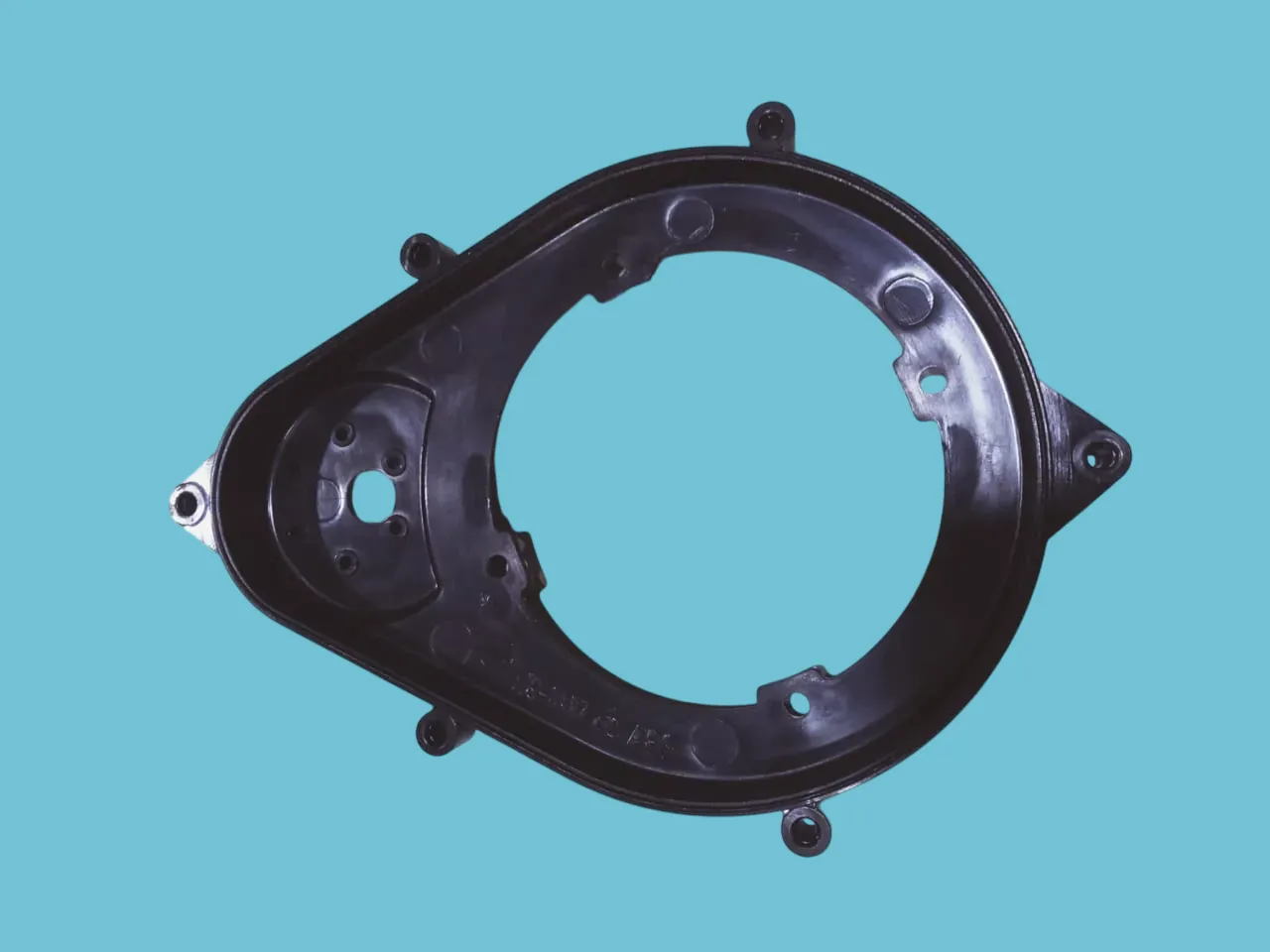

Manufacturer of Pressure Die Casting Dies, Investment Casting

dies, Blow moulds, Rubber Moulds etc.

Die & Mould Solutions, established in 2011, is a leading

manufacturer of plastic injection moulds and PDC dies. With an

annual turnover of ₹10-50 crore and a team of 65+ employees, the

company serves top clients like PG Electroplast, Atomberg, ITW,

Godrej Interio, Bharat Electronics, DENSO, BAJAJ, SANDEN

VIKAS(INDIA) LTD., Herman Miller, ECIL- Electronics Corporation of

India limited. ISO9001-certified, it specializes in exports and

has a sales presence in Hong Kong, ensuring global quality

standards.